Damascus Steel, no longer just for royalty!

Beautiful Things

The Barefoot Forge crafts custom designed Damascus Steel rings for any occasion! Our unique rings are prefect for weddings, engagements, commitments, or just general enjoyment. Our rings are hand crafted in house and made completely in the USA.

What is Damascus Steel?

Damascus steel is a unique and beautiful product produced by meticulously combining two dissimilar metals to produce a product with properties of each constituent material. This ancient process was used to gain the beneficial properties of two completely dissimilar alloys in an effort to produce a perfect product in terms of strength and edge retention in swords. By combining a low carbon and corrosion resistant steel alloy which may not be overly strong, with a high carbon steel which may be overly brittle, craftsmen were able to produce a material unique for its time. This material would have the necessary flexibility and corrosion resistant as well as the solid edge retention and strength required for a blade which was dramatically better then any available blade at the time. Some ancient swords employed thousands of layers of material in order to create micro-grain structure to even further homogenize these properties.

The unique patterns created by the subtle blends of dissimilar materials resulted in some unintentional beauty, a property we have mastered displaying.

Modern "Damascus" steel is more properly referred to as "Pattern Welded Steel", as the process and properties share very little with the ancient ways, but regardless......it's awesome stuff!

Why Damascus Steel?

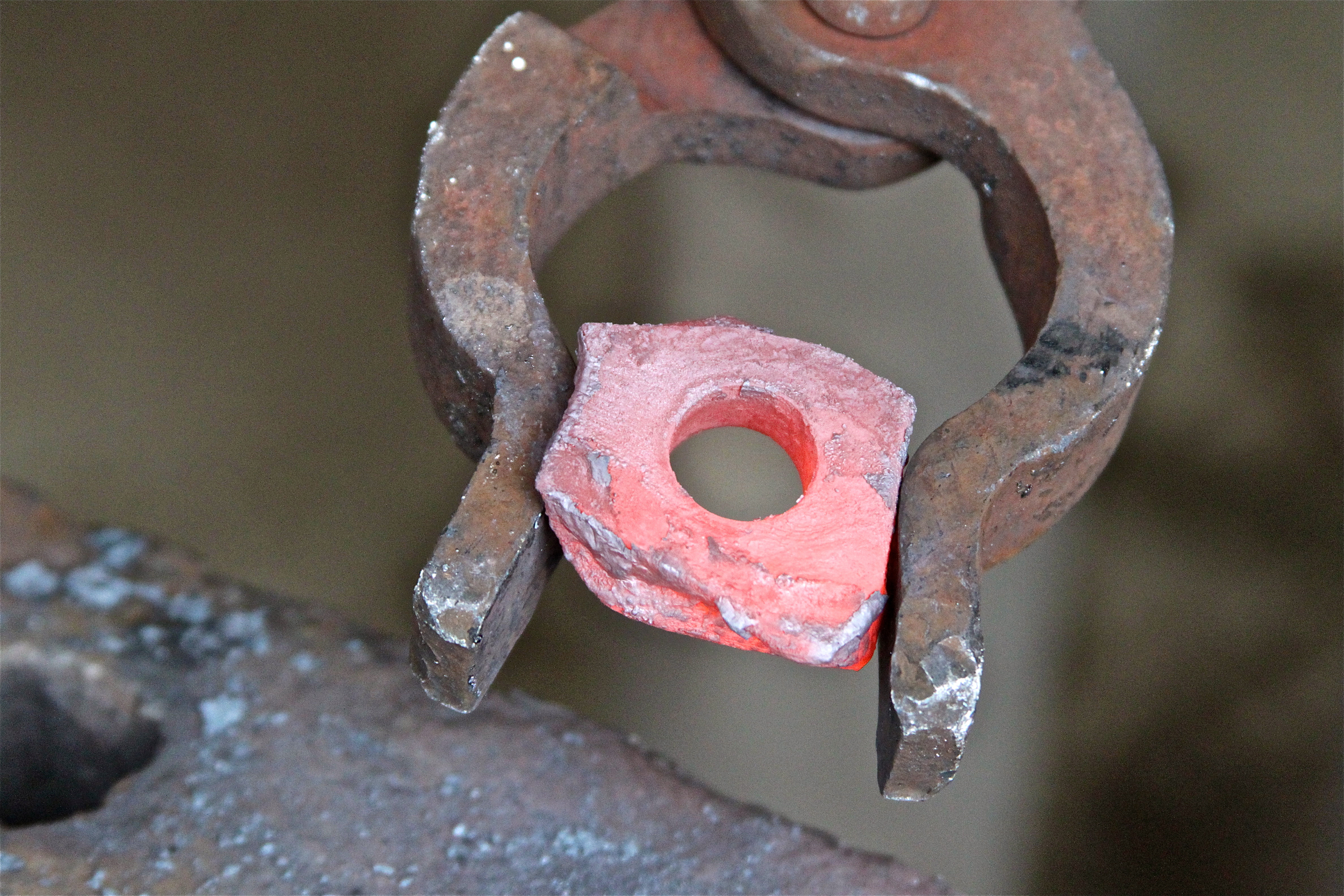

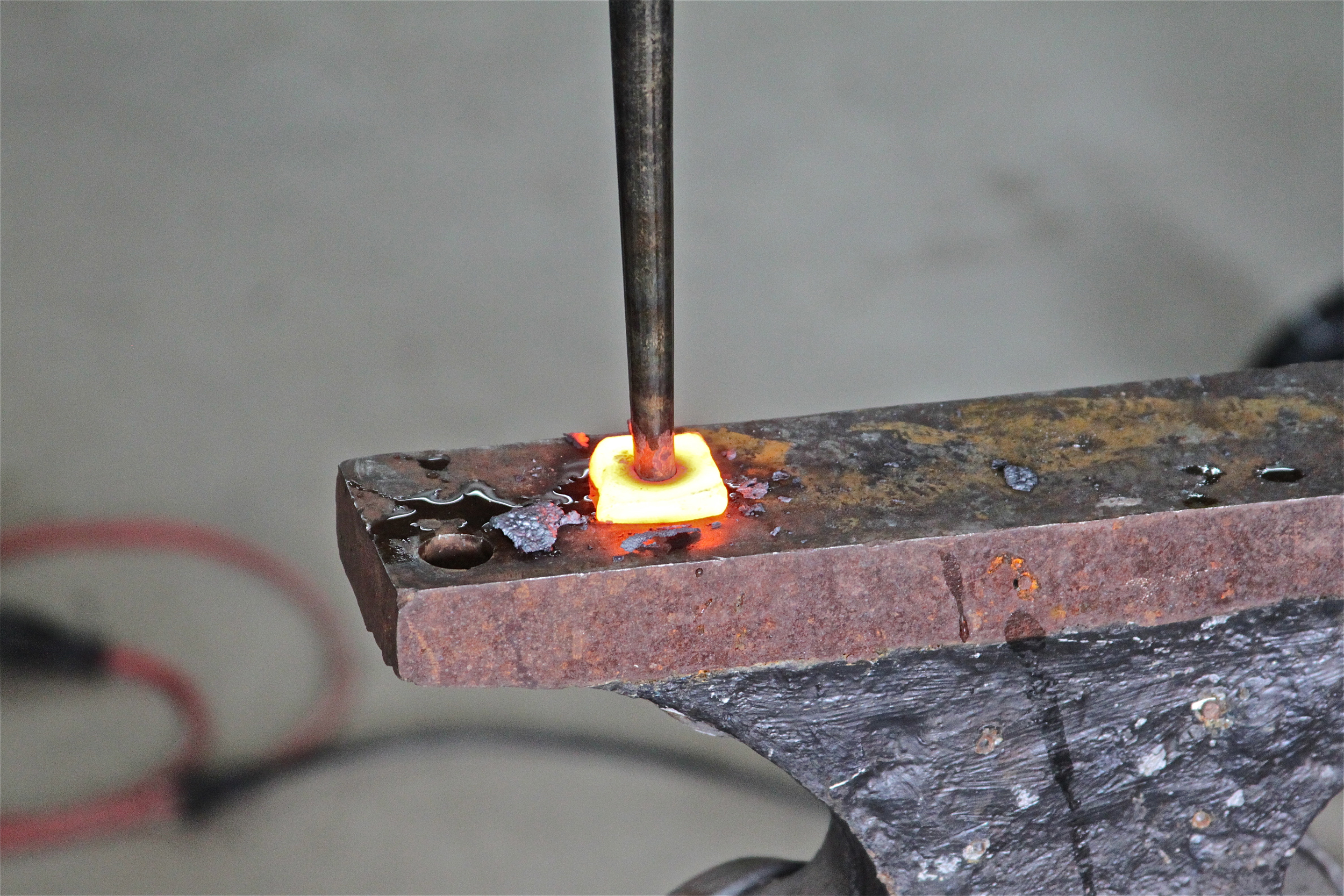

The dissimilar properties of the alloys used can result in some spectacular and surprising patterns. By meticulously crafting a block of material with the proper layer count and thicknesses, this solid billet of material can be forged into rings which show spectacular pattern. The unique nature of the pattern expressed is a result of mistakes, flaws, and the general rough nature of the forging process. No two rings will ever be the same and much like your finger print, your ring will be truly unique to your finger.

The result is a ring which looks like it's crafted of wood grain, but contains the strength and durability of our unique alloy combinations.

100% Handmade in the USA~!

At the forefront of our craft is a hammer.

We build our blocks of damascus by carefully forge welding and folding multiple layers of dissimilar alloys together using heat and hammers. An antique power hammer, along with brute force and a massive sledge hammer are used to forge a large solid billet which is then cut and shaped into your ring. A series of speciality hammers and custom tools are then used to forge a precise ring, followed by a combination of abrasive belts and a small hand operated lathe to refine the rough characteristics of the hand forged ring into a finished piece of jewelry.

Crafted In Pittsburgh PA, the Crucible of American Industrialization.

Pittsburgh PA is legendary for its Steel production over the course of its history. Since the 1850s, the city of Pittsburgh was world renowned for its production of speciality steels used in craft industries such as this. As time went on, Pittsburgh produced more then half of the nation's steel and thus providing the back bone of the industrial revolution in America. Pittsburgh Steel won World War Two, producing more steel then the countries of Italy, Germany, and Japan COMBINED.

In the shadow of this great steel city, on a beautiful and historic 50 acre organic farm just outside the range of industrial mechanization, The Barefoot Forge was born. Utilizing hand crafted and in many cases antique tools, in a rustic barn on a scenic farm, we craft spectacular custom rings from a self taught blend of traditional and creative modern methods. The shop is available for visits upon appointment and we'd love to share our craft with anyone interested!

“We don’t make mistakes, just happy little accidents”